INDEMAK

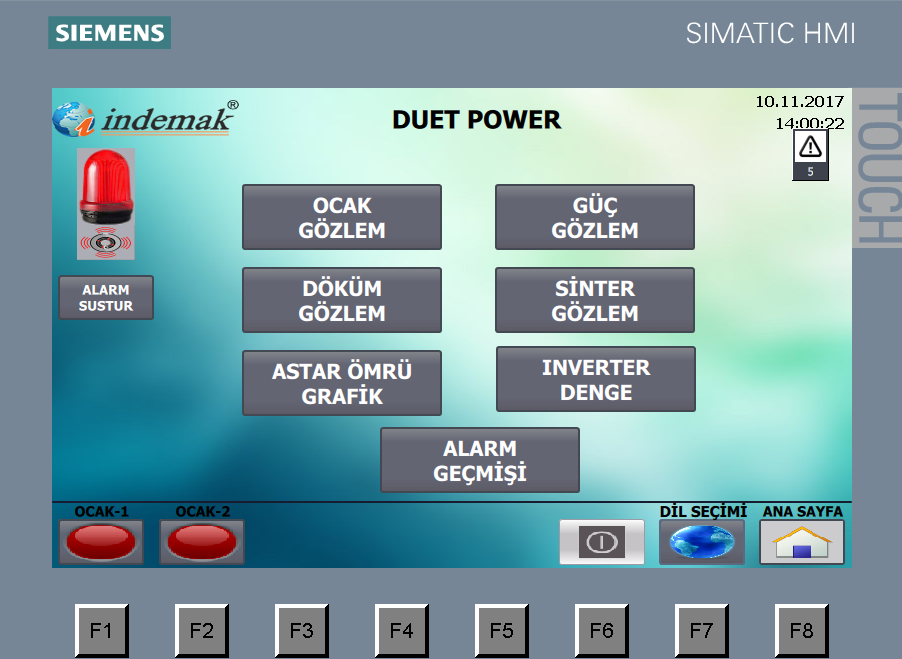

The melting assistant software, which is the integration of PLC systems into melting furnaces, offers different experiences

and features to users. These features aims to minimize operator errors and energy costs in melting furnaces by assisting the operator, are as follows.

• Refractory life monitoring screen

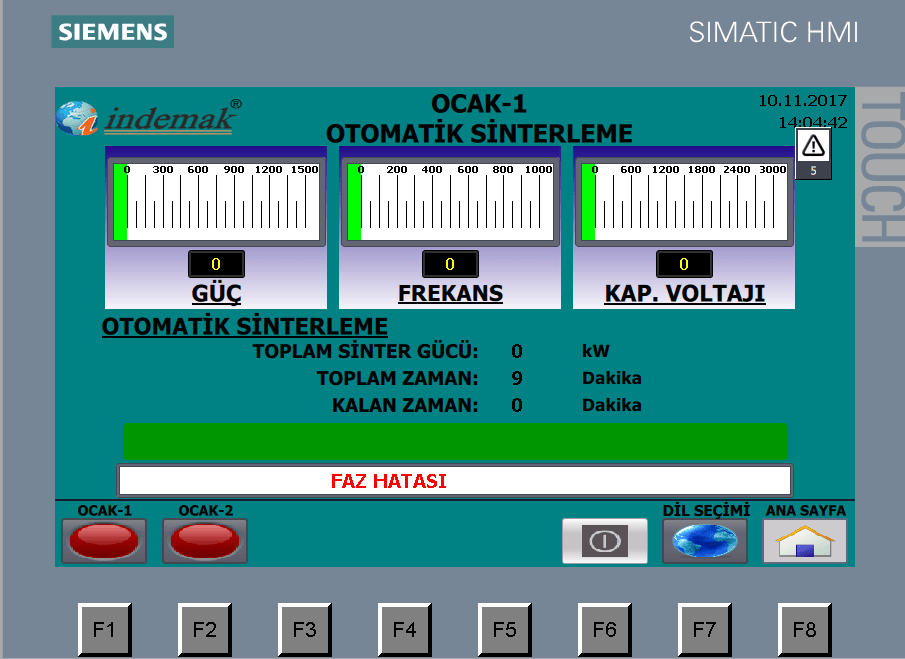

• 5 different sintering recipes for different refractory materials

• Power consumption reduction and less number of temperature measurements thanks to the semiautomatic melting software connected to the weighting system

• KWh limited melting mode

• Lining preheat mode

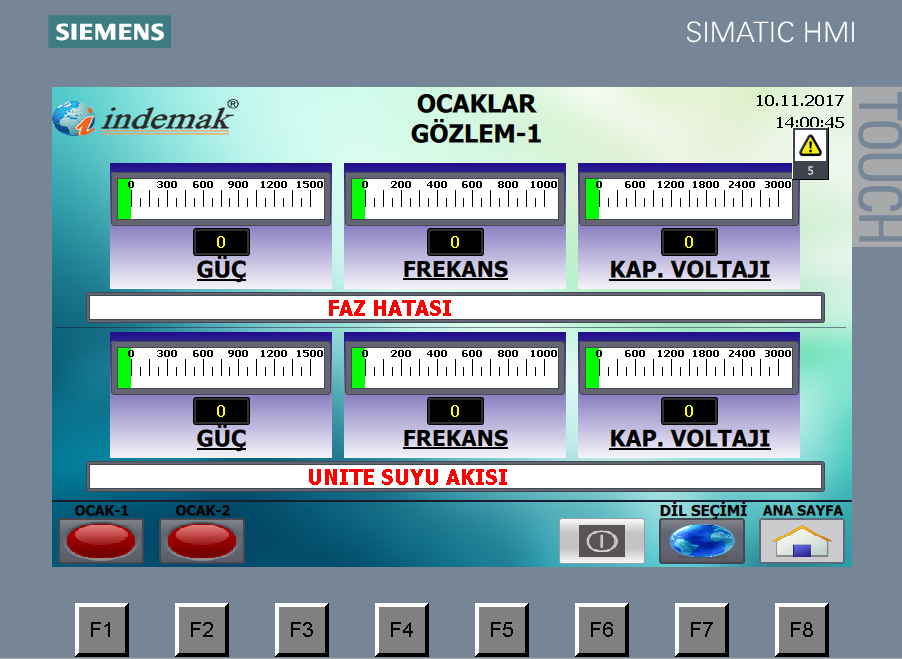

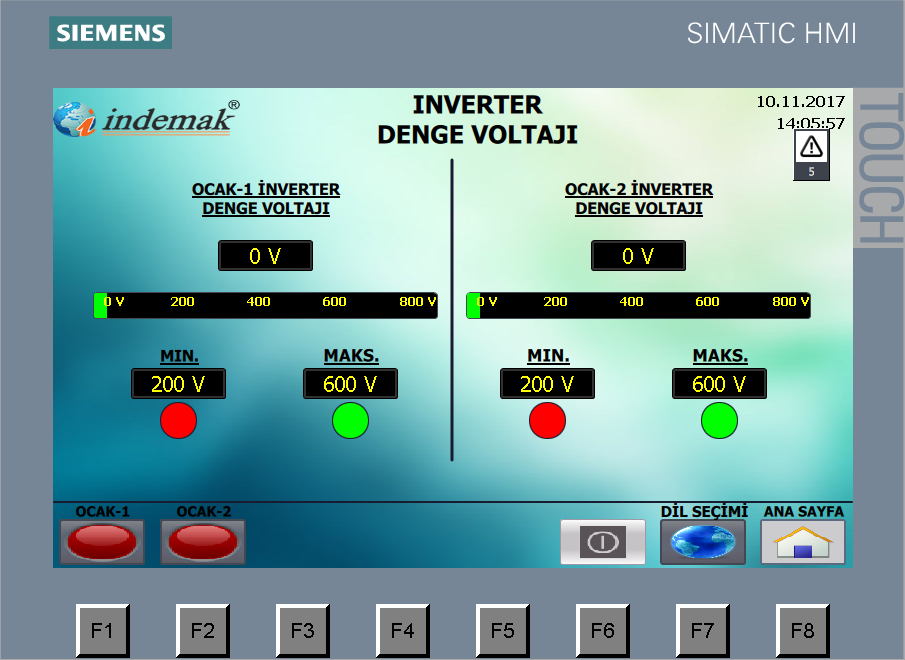

• Fast detection of thyristor faults with inverter balance voltage measurement

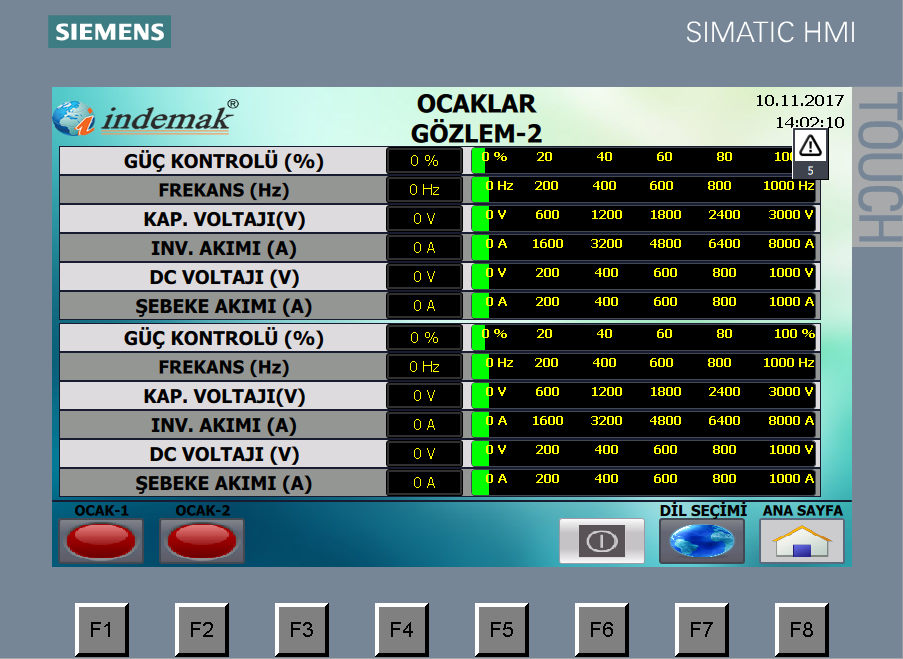

• Monitoring of the parameters of the melting furnace with the furnace observation menu

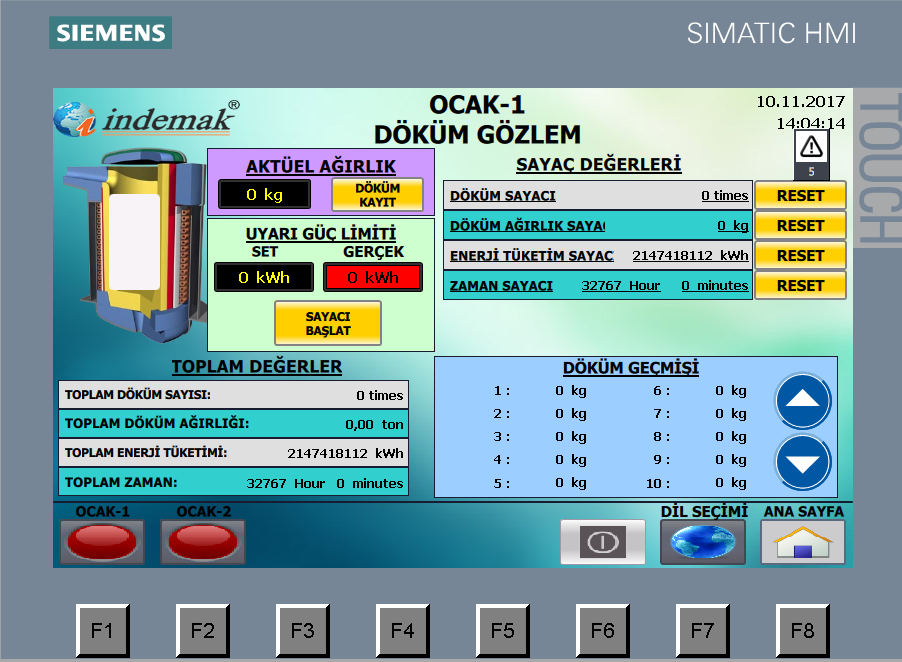

• Monitoring of data such as weighting system information, number of castings, power consumption on the casting observation screen

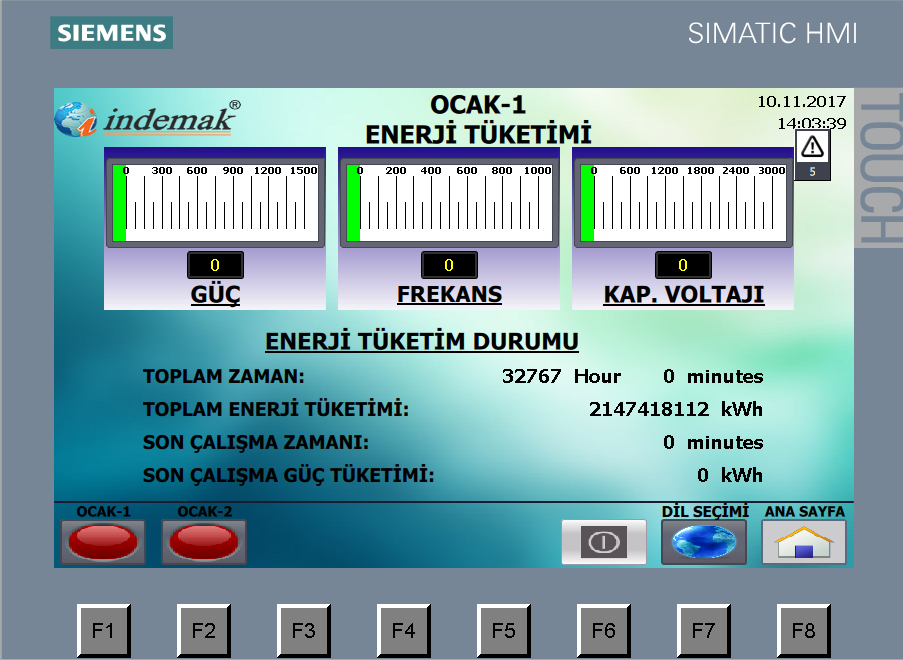

• Monitoring of energy consumption as final and total breakdown

• Monitoring of energy hose currents and detection of energy hose breakage

• Monitoring and recording of alarms and errors (daily, weekly, monthly)

• User-friendly screen design in different languages such as English, Russian and Turkish

• Monitoring of power unit input phase currents and detecting the malfunctions may arise from it

• Minimizing human-induced failures and humaninduced excess energy consumption

• Optimizing melting processes with addable sensors

• Facilitating the detection of faults thanks to the Internet connection

• Expandable with optional additional software